Big Achievements After Struggle

It’s a long, hard journey to sustainable packaging, as big achievements are often after great struggles. With the increasing environmental concerns, more businesses are switching towards green practices over time. This has opened new ways to eliminate plastic waste and making brands move towards eco-friendly packaging. These promises are a win situation for the brand’s public relations and the environment. The most important thing to consider here is that how challenging is it for packaging manufacturers to cope with this change.

Table of Contents

ToggleThe transition towards Greater sustainability is with Careful Considerations:

Packaging affects the complete supply chain, starting from the manufacturer to the brand owner and retailer, even the waste and recycling organizations. Given the complexities and often-changing tide of public opinion, the biggest challenge for packaging manufacturer is to determine which new material is best to invest in. When it comes to eco-friendly boxes, some businesses feel reluctant in developing a new piece of packaging, which they do not know will be successful or not. Once there was a push for light-weight material, so the packagers shifted from glass to plastic bottles. Now the plastic is on the blacklist. If a business starts manufacturing cardboard boxes considering it a need of time, again other sustainability elements like recycling are out of its control. Therefore, switching to a new packaging and printing option demands careful consideration.

The Cost of Eco-Friendly Packaging can be Substantial for the Manufacturers:

In most of the countries including the UK, recycling and collecting of waste are not co-ordinated centrally, rather done by local authorities. This creates inconsistency and hinders the closed-loop recycling of corrugated boxes, natural Kraft packaging, and other paper products. A year back, Unilever Australia called for the standardization of the waste management laws across three tiers of the government. It stated that different recycling policies were slowing down the progress to achieve sustainability goals. Such a disjoint in waste management processes hinder the investment in recycling facilities and material supply for packagers. It is even more challenging for developing countries, which have bigger pollution problems and where the recycling process is significantly less advanced.

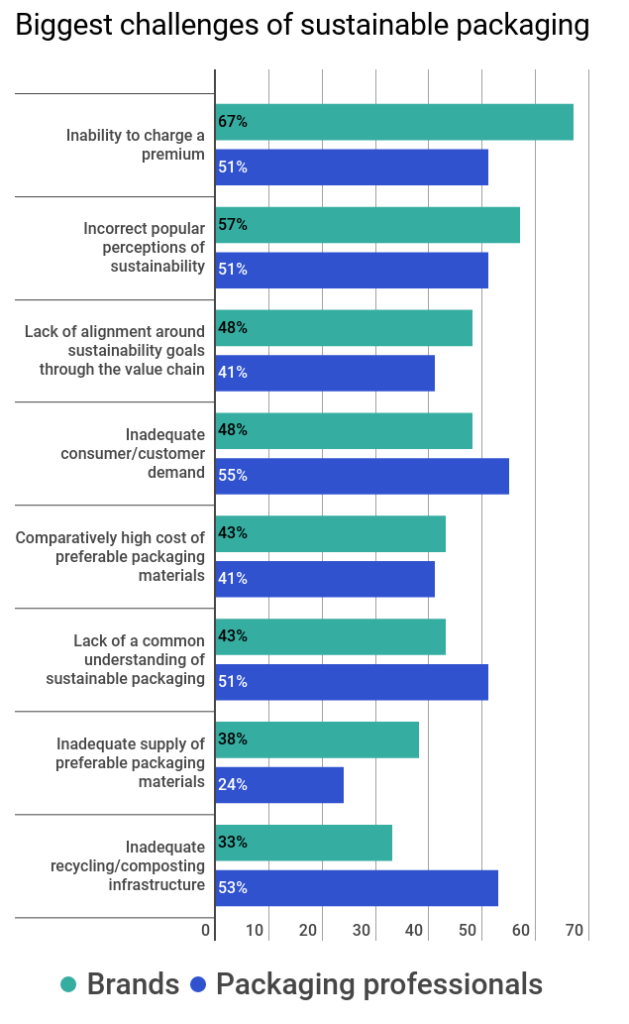

Biggest Challenges of Sustainable Packaging:

When a business starts producing brown Kraft boxes and other recycled material, on average, it is more expensive than virgin ones. The main reason for this increase in cost is that the scale of production is different. Additional research and development investment is needed to change the machine line. For brands, it will be near about 1 per cent on cost, but for the manufacturers, it will be 10 per cent because they have to make a large upfront investment. These costs are reduced slowly when the volume or order size of custom cardboard boxes increase and the actual investment is recovered.

Benefits of becoming more Eco-Friendly:

Although, there are considerable challenges in the way to sustainability, at the same time there are numerous benefits of becoming more eco-friendly.

• Sustainability also goes hand in hand with cost reduction if implemented correctly. Especially during the design phase, if a manufacturer goes for reducing the packaging size of custom boxes along with the material used, it may result in a significant reduction in cost particularly for large order size.

• In the same way, designing perfect sized custom shipping boxes not only enhances the level of protection but also eliminates the need for excessive filler packaging. This helps in reducing your costs further.

• Made-to-fit technology is perfect to be used for e-commerce packages. The printed packaging boxes designed in this way achieve a 99% fill rate for every shipment. It reduces the use of fuel, transportation costs, dimensional weight shipping charges, and carbon emissions.

• Recycling Kraft boxes and other paper packaging products prove highly beneficial. They save a large amount of water, fuel, electricity, landfill space, and other natural resources.

• Green packaging allows you to reduce, reuse, and recycle. As stated earlier, you can reduce the use of raw material. Custom printed boxes made up of cardboard can be stored and reused several times without affecting their quality and durability. They are easy to recycle and produce no waste, thus meeting the biggest goal of sustainability.

• Eco-friendly custom packaging boxes improve your brand image. According to research, the consumers of today are inclining more towards sustainable brands. This improves your sales revenue and helps in increasing your customer base.

Investing in recycled boxes and sustainable technology usually pays for itself in a year. As this packaging is flexible so it might be challenging for everyone in the future. However, sustainability is really exciting if you are investing in the right packaging solutions. It provides big opportunities for the organization to grow and flourish.