Implants in Fracture Fixation

Table of Contents

ToggleGeneral requirements

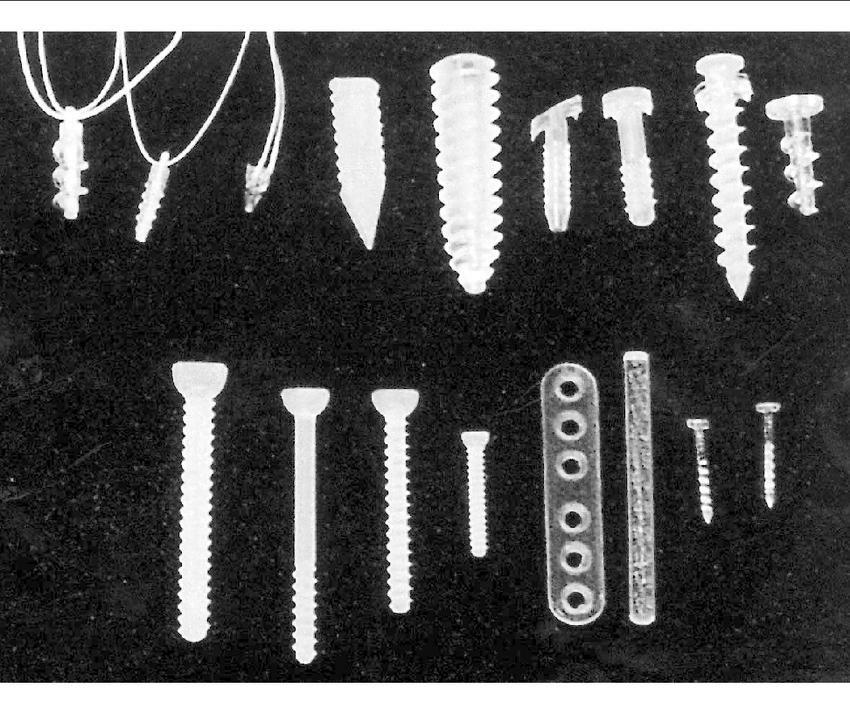

In terms of internal fixation, the final choice of material is metal. It is because this material has decent ductility and offers excellent strength and stiffness. The metal implants in today’s time are tolerated well. The metal implants are generally made of titanium or stainless steel. Besides metal, there are various other materials such as carbon composites, ceramics, polymers, and a plethora of degradable materials which are used. These materials are used for the applications that are unique in terms of the biologically derived elements.

The trauma implant materials are used for fixation internally. These materials should have specific fundamental necessities, evident among which is dependable on capacity, and negligible reactions are comparably significant. Less apparent is the requirement for suitable dealing with characteristics. The determination of material properties and embed configuration must react to a few frequently clashing necessities, which will be utilized as rules as the various inserts are examined. Our conversation is proposed to offer a legitimate reason for the appropriate determination of materials instead of giving point-by-point specific and essential information.

Special requirements

Stiffness, as a term, signifies the relation between the deformation and the applied load. A bone plates fracture is generally taken as the bone is no stiffer. Osteosynthesis is the process through which bones stiffness is restored temporarily. On the other hand, the healing of the fracture is restored permanently.

In terms of considering an implant (such as fixator of the external forces, nail or plate_ the fracture spanning, for instance, in the limb which is on the lower side, the plant’s stiffness is known to prevent the site of the buckling fracture. To ensure that proper healing of the device takes place, there must be a reduction in the mobility of the fracture to a certain level of criticality at the point where the repair tissue will be seen forming.

The implant’s stiffness does seem to be a result of the material stiffness, but more significantly, from that stiffness, which is factored out by the dimensions or the shape of the implant. As an instance, sometimes, the stiffness of the material is considered of titanium, which is regarded as half the amount of stainless steel. Hence, the increase in the level of the thickness of the plate, which is standard by a little tenth, seems then to restore the stiffness of the plate’s bending.

In the past, there have been propositions used for the Orthopaedic implants with materials of varied “bone-like” compared to metals such as composites of carbon or plastic. Hence, there are still implants with extremely less amount of stiffness of the material; as a matter of fact, the rule offers, which is the balance considered as acceptable between the mechanical advantage and biological.

Hence such a material that is less stiff material does not help abolish the shielding the stress levels, where plastics do not seem to destroy, but instance leak, for instance, the additives. Hence, the properties of the mechanics in terms of the relaxation of stress in terms of the strength, and then there is less amount of flexibility in comparison to what is the ideal scenario for were applications of the clinical.

Moreover, the various researches have shown that short prognosis of the bone plate in terms of contact with any implants does not rely on the characterize may in terms of the stress limit (which unit area per focus); this eventually boils down to the rupture immediate. In terms of the fixation of the internally, then the resistance seems to get loaded repeatedly, which ultimately results in the loos of fatigues, which is far more essential than strength. Compared with the titanium steel, co., there is a little amount of resistance to the loads that are single but act as superior when there is some repetition of the high cycle loads for acting.